Polyacrylamide (PAM) plays a pivotal role in enhancing productivity and optimizing processes within the textile industry. This versatile polymer finds extensive applications ranging from dyeing processes to the treatment of various fiber materials, and even in the wastewater management of textile facilities.

In textile dyeing, PAM serves as a dispersant and additive, significantly improving the dispersibility and absorption of dyes. This ensures uniform and efficient dyeing processes while enhancing the color fastness of fibers, ensuring long-lasting color retention.

During fiber processing, PAM acts as an antistatic agent and lubricant, reducing friction between fibers and thereby enhancing their strength and softness. It effectively prevents static electricity build-up, reducing energy consumption during processing and improving overall production efficiency and quality.

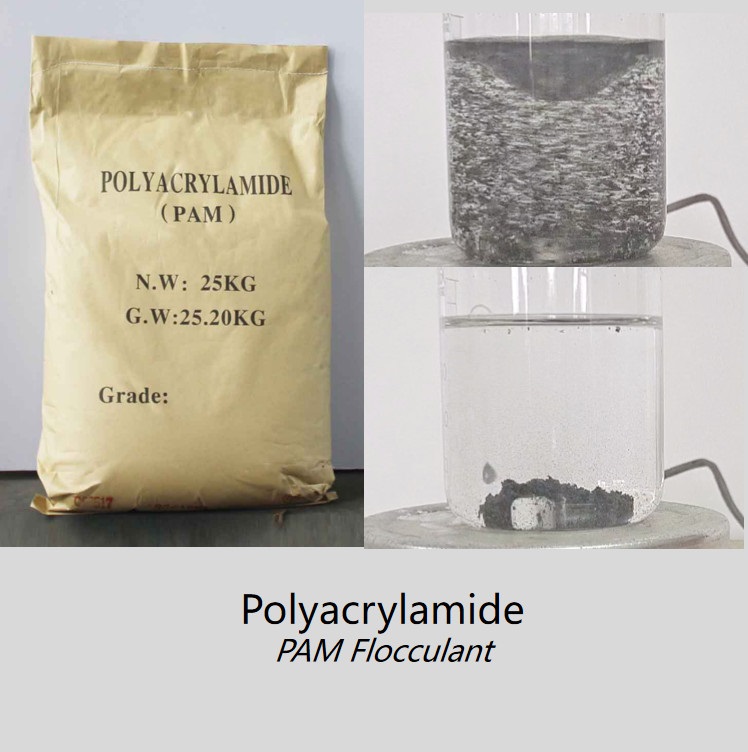

With increasing environmental regulations, wastewater treatment in textile manufacturing is crucial. PAM serves as an effective flocculant and precipitant, aiding in the removal of suspended solids, dyes, and organic matter from wastewater. When combined with other treatment methods such as biological or chemical processes, it helps meet stringent discharge standards and minimizes environmental impact.

In conclusion, Polyacrylamide’s applications in the textile industry extend beyond dyeing and fiber processing to encompass comprehensive wastewater treatment solutions. Its multifunctionality and efficiency make it indispensable in modern textile production. At TAIRAN CHEMICAL, we are committed to providing high-quality PAM products and tailored solutions, ensuring our clients maintain a competitive edge in the market.