Polyacrylamide Dosage in Water Treatment: Best Practices and Guidelines

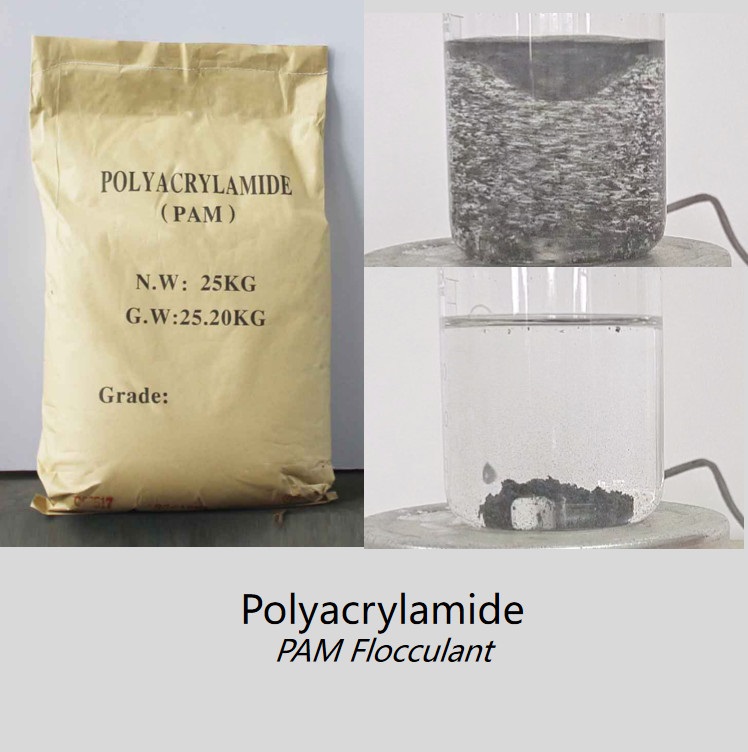

Polyacrylamide (PAM) is a versatile and effective polymer widely used in water treatment applications. It plays a critical role in flocculation, coagulation, and the removal of suspended solids from water. However, achieving optimal results in water treatment depends on the correct dosage of polyacrylamide. In this article, we will explore the best practices and guidelines for determining the right polyacrylamide dosage, ensuring maximum efficiency in water treatment processes.

The effectiveness of polyacrylamide in water treatment largely depends on the right dosage. Too much PAM can lead to excessive sludge formation, while too little can result in poor flocculation, inefficient water treatment, and potential operational issues. Accurate dosage ensures optimal polymer performance, reduces chemical waste, and maintains cost-efficiency.

Several factors influence the optimal dosage of polyacrylamide in water treatment:

Water Quality: The turbidity and composition of the water to be treated play a significant role. Water with higher turbidity or a complex mixture of contaminants requires a higher dosage of PAM for effective flocculation.

Type of Polyacrylamide: Polyacrylamide comes in various forms, including anionic, cationic, and non-ionic. Each type has specific properties that determine its dosage in different water treatment scenarios.

Flow Rate: Higher flow rates often require more polyacrylamide to maintain flocculation efficiency. Water treatment plants need to adjust the dosage based on the volume of water being processed.

pH Levels: The pH of the water affects the charge and behavior of polyacrylamide. Adjusting the dosage based on pH can help optimize its performance in coagulation and flocculation.

To achieve the best results from polyacrylamide, here are some best practices for dosage:

Conduct Jar Testing: Before large-scale application, perform jar testing to determine the optimal dosage for specific water treatment conditions. This helps assess the flocculation performance and ensures the right amount of PAM is used.

Start with Lower Dosages: It's recommended to begin with a lower dosage and gradually increase it based on the results of jar testing. Overdosing can lead to sludge buildup, which is both inefficient and costly.

Monitor Water Quality: Regularly monitor the water quality parameters (such as turbidity and pH) to adjust the dosage as necessary. Changes in water quality will require recalibration of the PAM dosage to maintain optimal treatment performance.

Adjust According to Seasonal Variations: Water quality can change with the seasons, especially in areas with varying precipitation. Be prepared to adjust the dosage during different seasons to ensure consistent water treatment results.

Use Automatic Dosing Systems: To achieve precise control, many water treatment plants use automatic dosing systems. These systems can adjust the PAM dosage in real-time, ensuring that the treatment process remains efficient and cost-effective.

To calculate the correct polyacrylamide dosage for water treatment, use the following general formula:

Dosage (ppm) = (Polymer required) / (Water flow rate)

Where:

Polymer required is the amount of polyacrylamide needed for effective treatment.

Water flow rate is the volume of water to be treated per unit of time.

It’s important to note that dosage is typically measured in parts per million (ppm), and a precise calculation will depend on the specific water treatment requirements of your facility.

Improved Flocculation Efficiency: With the correct dosage, polyacrylamide enhances the coagulation and flocculation process, ensuring that suspended solids are effectively removed.

Cost Savings: Proper dosing minimizes waste and optimizes chemical use, leading to significant cost savings for water treatment plants.

Reduced Sludge Production: Overdosing can lead to excessive sludge formation. By using the right amount of PAM, the amount of sludge produced is minimized, reducing disposal costs and improving overall efficiency.

Enhanced Water Quality: Accurate dosing ensures cleaner treated water, improving the overall quality and meeting regulatory standards.

Determining the right polyacrylamide dosage is essential for efficient and cost-effective water treatment. By considering factors such as water quality, flow rate, and pH levels, and by following best practices like jar testing and monitoring, water treatment facilities can ensure that PAM is used effectively. With precise dosing, operators can improve flocculation, save costs, reduce sludge production, and achieve better water quality.

If you’re looking for high-quality polyacrylamide for your water treatment needs, TAIRAN CHEMICAL offers a range of PAM products designed to meet the specific demands of your facility. Contact us today for expert advice on dosing and to learn more about how our products can help optimize your water treatment processes.