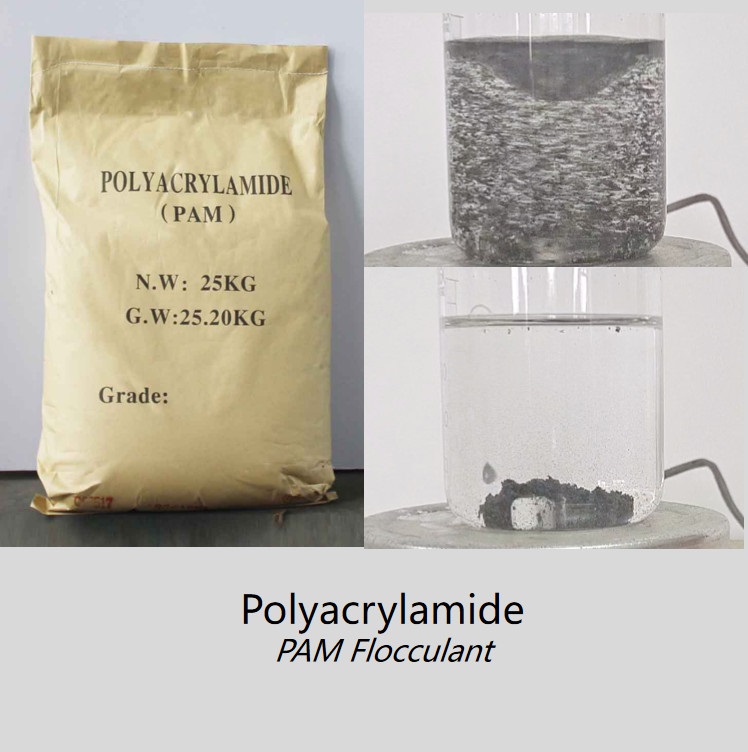

In many industries, flocculants are indispensable chemicals used to purify water by helping to remove suspended particles. These tiny particles can make water look cloudy. This can make the water unsafe for drinking and industrial use. Flocculants work by promoting the clumping or flocculation of these suspended solids, making them easier to remove.

Polyacrylamide (PAM) is a popular synthetic flocculant. It is versatile and effective in many uses. These include wastewater treatment, oil recovery, and soil management in agriculture.

Polyacrylamide is a high molecular weight polymer primarily composed of acrylamide monomers. A water-soluble polymer can dissolve into water to form a gel-like substance. The basic structure of PAM consists of long chains of acrylamide units that form random coils in solution.

These coiled structures are crucial for its flocculating ability. When you add PAM to water, its polymer chains interact with particles.

This causes the particles to form larger groups called flocs. These flocs then either settle at the bottom or rise to the surface. This depends on the type of flocculant used.

PAM can work as a coagulant aid or a main flocculant. This makes it very useful in industrial water treatment. The polymer is versatile because of different types like anionic PAM, cationic PAM, and non-ionic PAM. Each type serves specific applications based on the charge of the contaminants.

Polyacrylamide's flocculating power comes from its molecular structure. The long chains in PAM consist of repeating acrylamide units. Each unit has amide groups that attract charged particles in water. Here's a breakdown of how PAM interacts with water and particles:

Anionic PAM: This type has negative charges. It works well for treating water with positively charged contaminants, like metal ions or fine clay particles.

Cationic PAM: This type has positive charges. It works best for treating negatively charged particles, like organic contaminants or tiny suspended solids.

Non-Ionic PAM: This type has no charge. It is used in situations where charge-specific flocculation is not needed.

When PAM comes into contact with contaminated water, its long chains stick to the suspended particles. This creates a bridging effect. This process leads to the formation of micro-flocs, which, under agitation, will grow larger through coagulation and flocculation. Once the flocs grow large enough, you can easily separate them from the water.

PAM is often used in municipal wastewater treatment. It helps remove suspended solids, organic matter, and heavy metals. By adding PAM, small particles bind together to form larger flocs that gravity or filtration can then remove.

In industrial settings, PAM is often used in sludge dewatering. It helps separate water from sludge. This makes the sludge easier to handle and dispose of.

In the oil industry, companies use polyacrylamide in enhanced oil recovery (EOR) techniques. It is mixed with water floods to help push oil to the surface more effectively. The thick nature of PAM helps keep the flood stable. It also increases contact with the oil reservoir, which improves extraction efficiency.

Polyacrylamide is increasingly being used as a soil conditioner to improve water retention in agricultural settings. PAM helps stop soil erosion and improves soil structure. This keeps moisture in the soil and helps crops grow better, especially in dry areas.

High temperatures can cause PAM to degrade, reducing its flocculating ability. On the other hand, cold temperatures may slow down the reaction, as viscosity increases and particle collisions decrease.

The type and concentration of impurities in the water determine the amount of PAM required. The size and charge of the suspended particles affect how PAM interacts with them. This influences the amount needed for the best flocculation.

At Tairan Chemical, we specialize in the production and supply of high-quality polyacrylamide products. We provide anionic, cationic, and non-ionic PAM. We design our solutions to meet your specific needs. Our products are widely used across industries such as:

Municipal and Industrial Water Treatment

Oil and Gas (Enhanced Oil Recovery)

Soil Conditioning and Agriculture

Polymer Gel Electrophoresis

Tairan Chemical is your trusted partner for polyacrylamide products. We have strict quality control and care about customer satisfaction. Our products meet the highest standards.

1. Is Polyacrylamide safe for water treatment?

Yes, when used within regulatory guidelines, PAM is safe for potable water treatment. It is widely approved for use in municipal water purification and wastewater treatment processes.

2. How is PAM applied in water treatment?

Typically, operators dissolve PAM in water to form a solution and then dose it into the water treatment system. The optimal dosage depends on the specific water conditions and the type of contaminants present.

3. What makes Tairan Chemical's Polyacrylamide products stand out?

Tairan Chemical manufactures its PAM products with the highest purity standards. We offer customized formulations based on your application requirements, ensuring the best performance in every treatment process.

Polyacrylamide is very versatile and easy to use. It is also effective, making it a popular flocculant in many industries. PAM is important for wastewater treatment, soil conditioning, and oil recovery. It helps improve water quality and makes processes more efficient.

With Tairan Chemical’s high-quality PAM products, you can ensure optimal performance for your specific application. Contact us today to find out how our Polyacrylamide solutions can help you with water treatment and industrial goals.