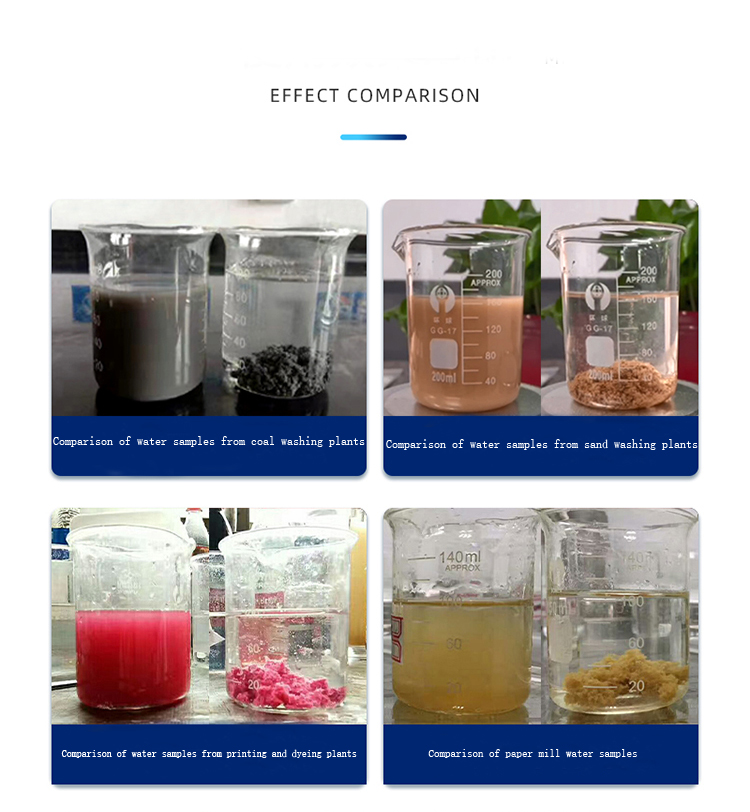

For problems such as wastewater and sewage treatment, a variety of agents can be used at present, among which polyacrylamide is particularly effective, with fast flocculation and obvious purification effects.

Anionic polyacrylamide (A PAM) is a water-soluble polymer, a product of polyacrylamide (PAM), with a white powder appearance, solubility, viscosity, toughness, and non-flammability (low). Molecular weight varies from 6 million to 25 million, good solubility in water, soluble in water in any proportion, insoluble in organic solvents. It is mainly used for flocculation and sedimentation, precipitation and purification treatment of various industrial wastewater such as steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, copper mine wastewater, coal washing wastewater, sewage dewatering, etc. It can also be used for drinking water purification and purification treatment.

Anionic polyacrylamide (A PAM) has the functions of purification, promotion of sedimentation, promotion of filtration, concentration, etc., so it is widely used in various industries, and wastewater treatment is especially obvious. The molecular chain contains a certain amount and sexual organs, which can adsorb the solid particles floating in water, carry out inter-particle bridging or coalesce particles by electric charge to form larger solids, thus accelerating the settling of particles in suspension. It is very effective in promoting solution purification and filtration, etc.

Features of anionic polyacrylamide (A PAM):

1. Good water solubility, and can be completely dissolved in cold water.

2. Adding a small amount of anionic polyacrylamide can achieve several times or even tens of times the flocculation effect of inorganic coagulant, and the flocculation speed is faster.

3. Combined use of anionic polyacrylamide and inorganic coagulant can achieve better effect.

How to use anionic polyacrylamide (A PAM).

1. When using, it is best to mix the aqueous solution first, observe the ratio to determine the use, and use neutral nosocomial miscellaneous when mixing the solution.

2.Dissolve by spraying evenly in the water mixed with anionic polyacrylamide products and stirring to 100~300rpm. appropriate heating (below 60) can accelerate the dissolution.

3. Adjust the PH value of the treatment solution to make the anionic polyacrylamide product work adequately (choose the proper PH value and usage amount by experiment). .

4. When adding the solution of anionic polyacrylamide products, it should speed up the mixing with the treatment solution, and slow down the volatilization speed after the appearance of the solidification to speed up the growth and settlement of the solidification. Storage and precautions of anionic polyacrylamide (A PAM):

1. It is easy to dissolve in contact with water and moisture, so it should be stored in a cool and ventilated dry place in general.

2. Skin contact: Take off the contaminated clothes and wash the skin thoroughly with soapy water and water. Eye contact: Lift the eyelids, flush and treat with flowing water or saline. Ingestion: It is proved through animal experiments that the product will not be poisoned after ingestion.

3. It is recommended to use the product within one year after production. When preparing the solution, configure as much as possible at the same time. The viscosity of the formula solution decreases over 24 hours and the use effect is reduced.

4. When preparing the solution, do it in aluminum or plastic barrels, not in iron containers for blending and storage.

Coal plant coal sludge water treatment generally uses the "rotator-concentrator-pressure filter (coal sludge sedimentation tank)" treatment process. Usually it is purchased with polymer coagulant (polyacrylamide). The polymer coagulant comes into contact with the coal slurry particles or coal slurry colloid, neutralizes the electrical properties of the coal slurry surface, reduces the surface energy, and causes the coal slurry particles to coalesce and precipitate. The molecular weight of polyacrylamide is generally between one million, and different particle size of coal slurry water needs to use coagulant with different molecular weight. Polyacrylamide can be divided into three types: anionic polyacrylamide, cationic polyacrylamide and non-ionic polyacrylamide. When using polyacrylamide to treat water, make sure that the type matches the pH of the coal sludge water. Anionic polyacrylamide is alkaline coal sludge, cationic polyacrylamide is acidic coal sludge, anionic type and cationic polyacrylamide mixed use, coal sludge flocculation and sedimentation effect is better.

Anionic polyacrylamide (A PAM) is a water-soluble polymer, mainly used for coagulation and sedimentation, sedimentation and purification treatment of various industrial wastewater (such as steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, coal washing wastewater and other sewage treatment, sludge dewatering, etc.). It can also be used for the purification and purification treatment of drinking water. As the molecular chain contains a certain number of polar groups, it can adsorb the solid particles floating in water, make the bridge between the particles or coalesce the particles by electric charge to form larger solids, thus accelerating the settling of the particles in suspension. Solution purification, promote filtration and other effects are significantly accelerated.

1, clear purification role. 2, to promote the role of settlement; anionic polyacrylamide, filtration to promote the effect; 4, concentration and other roles.

Anionic polyacrylamide is used in industrial wastewater treatment. Especially the suspended particles, high coarse concentration, particles with positive charge, the PH value of water is better for the treatment of wastewater from steel plants, electroplating plants, metallurgical wastewater, coal washing wastewater, etc. Drinking water treatment. Many tap water plants in China are more turbid because of less river cement and high mineral content, after precipitation treatment, but still can not meet the requirements, need to put in coagulant to make the water clean, many tap water plants use weapons coagulant, but due to the large amount of input, resulting in an increase in the amount of sludge, the effect is not good, so use anionic polyacrylamide as coagulant, the amount of input is 50 of inorganic coagulation, especially our The company produces polyacrylamide, residual monomer used as a starch plant and alcohol plant for the recovery of lost starch and alcohol.

Translated with www.DeepL.com/Translator (free version)