In water treatment, flocculants are high–molecular–weight polymers that promote aggregation of fine particles (flocculation), whereas coagulant aids are additives that enhance coagulation, and conditioners (dewatering agents) help prepare sludge for solid–liquid separation. A flocculant (often called a coagulant aid when used with a coagulant) neutralizes charge or bridges particles so they clump together. A coagulant (such as aluminum or iron salts) destabilizes colloids; a coagulant aid (usually a polymer) boosts the coagulant’s performance. A sludge conditioner – also termed a dewatering agent – is added before dewatering and can be either a polymer or a metal salt. In practice, “the same agent can be applied both as a flocculant in the treatment of wastewater and as a conditioning agent (dewatering agent) in residual sludge treatment”tairanchemical.com. Notably, polymers used as flocculants (e.g. PAM) can also serve as sludge conditioners, while coagulants in water treatment (e.g. ferric chloride) become part of the sludge-conditioning mix.

Flocculants are chemicals that reduce the stability of dispersed particles, causing them to aggregate into larger flocs that settle or filter outepa.wa.gov.autairanchemical.com. They are broadly classified as inorganic, polymeric, or natural flocculants. Inorganic flocculants include aluminum and iron salts (e.g. alum, ferric chloride, ferric sulfate) which hydrolyze to form precipitates that sweep particles out of solution. Inorganic polymeric flocculants are pre-hydrolyzed metal salts (e.g. polyaluminum chloride, polyferric sulfate) that provide stronger, more stable flocs at lower doses. Organic polymeric flocculants are high-molecular-weight materials (usually synthetic) such as polyacrylamide (PAM) and polyethyleneimine. These water‑soluble polyelectrolytes carry charged groups (anionic, cationic, or nonionic) that bridge between colloidal particles or neutralize charge, pulling particles together. For example, anionic PAM targets positively charged colloids, while cationic PAM is effective for negatively charged particles.

Flocculant types: Polyacrylamide (PAM) is one of the most common flocculants in water treatmenttairanchemical.comarchive.epa.gov. It is available in anionic, cationic, and nonionic grades, each suited to different feed water and sludge. Nonionic PAMs (neutral charge) are versatile across pH rangestairanchemical.com. Cationic PAMs are preferred for organic sludges (strong negative charge) and accelerate dewateringtairanchemical.com, whereas anionic PAMs work best on inorganic or weakly charged particles. Inorganic flocculants are generally cheaper and more traditional, but polymers like PAM achieve flocs that settle faster and cake more easily with smaller dosagesepa.wa.gov.autairanchemical.com.

Flocculation process: Typically, flocculants are added in a rapid-mix or flocculation tank, followed by slow mixing (tens of seconds to minutes) to allow polymer chains to bridge particles. The resulting flocs then either settle in clarifiers or are removed by filtration. This is a relatively established and cost-effective processpubmed.ncbi.nlm.nih.govwww3.epa.gov. For example, research reviews note that “coagulation/flocculation is a relatively mature, cost-effective, user-friendly sludge dewatering technology” because it effectively reduces water content of sludge by forming settleable flocspubmed.ncbi.nlm.nih.govepa.wa.gov.au.

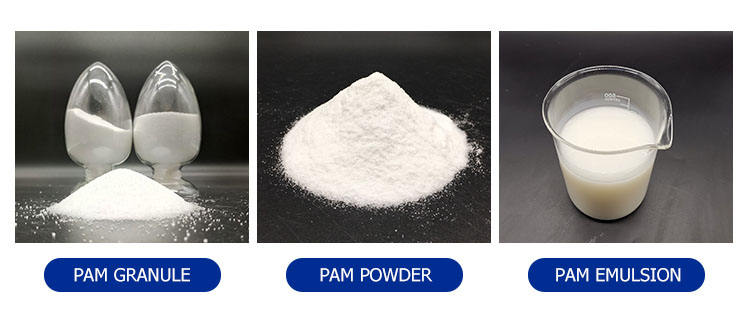

PAM is supplied as powders, granules, or emulsions. Its long-chain polymer molecules adsorb onto particles and form bridges, creating flocs for sedimentation and filtrationtairanchemical.comwww3.epa.gov.

Polyacrylamide is a high-molecular-weight acrylic polymer and one of the most widely used organic flocculants. In water, PAM molecules form coiled polymer chains that attach to suspended solids, creating a bridging effectepa.wa.gov.autairanchemical.com. As particles stick together, they form micro-flocs that rapidly grow under mixing to settleable flocs or filter cakes. PAM excels at solid–liquid separation: “Polyacrylamide (PAM) is a highly effective flocculant used in water treatment, sludge dewatering, and industrial processes”tairanchemical.com. Its high molecular weight and adjustable charge make it ideal for enhancing sedimentation and filtration efficiency. For example, cationic PAM (CPAM) with high charge density “accelerates sludge dewatering, enhances solid–liquid separation, and reduces processing costs”tairanchemical.com. Nonionic PAM dissolves quickly and works across wide pH rangestairanchemical.com. All forms significantly improve flocculation: one source notes PAM’s benefits include “increased solids removal efficiency” and “reduced sludge volumes” in treatmenttairanchemical.com.

Inorganic flocculants: Aluminum sulfate, ferric chloride, ferrous sulfate, etc., are cheap and readily available. They work by forming metal hydroxide precipitates that entrap particlestairanchemical.comepa.wa.gov.au.

Polymeric (inorganic): Polyaluminum chloride (PAC) and polyferric sulfate (PFS) are pre-polymerized metal coagulants. PAC, for example, “is a highly effective coagulant widely used in drinking water purification, wastewater treatment, and industrial water treatment. PAC helps in flocculation and clarifying water, efficiently removing impurities and suspended solids”tairanchemical.com. These inorganic polymers react more gently than raw salts, yielding stable flocs.

Organic polymers: Polyacrylamide (PAM) variants and synthetic polyelectrolytes are the mainstay for flocculation and sludge conditioningepa.wa.gov.auwww3.epa.gov. They have high flocculation efficiency, low required dosages, and no corrosive effects. Natural biopolymers (e.g. chitosan, starch derivatives) are also used in some plants as eco-friendly flocculants.

Coagulation is the process of destabilizing and aggregating particles, often by adding metal salts. A coagulant (e.g. alum, ferric sulfate, PAC) neutralizes charges and forms hydroxide precipitates that enmesh particles. Coagulant aids (or flocculant aids) are usually polymeric flocculants added alongside or after the coagulant to strengthen floc formation. For example, a water treatment process might add alum to quickly form microflocs, then dose a small amount of PAM as a coagulant aid to bridge and enlarge those microflocs into larger, faster-settling aggregates.

Common coagulants include aluminum sulfate, ferric chloride, and inorganic polymers like polyaluminum chloride (PAC). PAC is especially popular; as noted in Tairan’s product literature, “Polyaluminum Chloride (PAC) is an advanced coagulant used in water treatment for clarifying drinking water and industrial wastewater. Known for its high efficiency, PAC improves water quality by removing suspended solids and organic contaminants”tairanchemical.com. Other coagulants include polyferric sulfate and metal hydroxides. Coagulant aids are often polymers: for example, a low-dose polymer added to improve solids capture. The EPA notes that polymers (high-MW compounds) in precipitation processes can be used for charge neutralization, bridging coagulation, and also “as filter aids and sludge conditioners.”www3.epa.gov This highlights that polymeric coagulant aids and flocculants overlap with conditioners in function.

While coagulants are primarily used to neutralize charge, coagulant aids provide a secondary mechanism. In many municipal systems, coagulants are added first for charge neutralization, and flocculant aids (often anionic or cationic PAM) follow for rapid floc growth. This two-stage approach (coagulation + flocculation) yields more robust flocs and clearer effluent than either step alone.

Sludge from water/wastewater treatment (e.g. solids from clarifiers or biological digesters) is often too wet for disposal or incineration and must be dewatered. Conditioning agents (dewatering aids) are added to the sludge to improve the efficiency of mechanical dewatering (e.g. in filter presses, centrifuges). Conditioners help by forming more filterable solids and releasing water. They include:

Inorganic conditioners: Typically metal salts. Common ones are ferric chloride (FeCl₃), ferric sulfate (Fe₂(SO₄)₃), and aluminum sulfate (Al₂(SO₄)₃). These work by precipitation and charge neutralization within the sludge. The original Tairan article notes that “the most effective, cheapest and most commonly used inorganic conditioners are mainly iron salts… and aluminum salts (e.g. ferric chloride, ferric sulfate, aluminum sulfate, polymeric aluminum chloride, etc.)”tairanchemical.com. Such inorganic conditioners are especially suitable for vacuum and plate-frame filtration systems.

Organic polymer conditioners: These are similar to flocculants (PAM and other polyelectrolytes) but generally used at lower dosages (0.1–0.5% of dry solids) for dewatering. High–molecular-weight PAM (often cationic or nonionic) is very effective: it forms dense flocs that release water under pressure. Cationic PAM is widely used for sludge with high organic content; nonionic or anionic PAMs can be used for inorganic sludges. The advantage of polymeric conditioners is low dosage and non-corrosivenesstairanchemical.comtairanchemical.com. For example, cationic PAM can dramatically reduce sludge volume and accelerate dewatering, as noted by its use in municipal and industrial applicationstairanchemical.comtairanchemical.com.

Sludge conditioner selection: The choice depends on sludge chemistry. In general, iron salts are preferred unless they cause problems (corrosion, odor), in which case aluminum salts or polymers are usedtairanchemical.com. Organic polymers (PAM) are often favored for thickened sludge or high-organic sludge, since they require far smaller doses and generate denser caketairanchemical.comtairanchemical.com. For instance, “for sludge with high organic content, the most effective conditioning agent is a cationic organic polymer with a high degree of polymerization”tairanchemical.com.

Flocculants, coagulants, and conditioners frequently overlap in use. Importantly, a polymer added during wastewater treatment may serve double duty as a sludge conditioner later. For example, a PAM flocculant used in clarifiers will largely end up in the sludge and continues to aid dewatering. Tairan’s guide confirms that “the same agent can be applied both as a flocculant in the treatment of wastewater and as a conditioning agent or dewatering agent in the residual sludge treatment process”tairanchemical.com. Similarly, a coagulant (like ferric chloride) added in clarifiers will carry into the sludge, effectively acting as a conditioner there. The terminology shifts: a chemical called a “coagulant” in the water phase is typically referred to as a “conditioner” in the sludge phasetairanchemical.com.

Dosage expressions differ: flocculant dosages in water treatment are mg/L of effluent, while conditioner dosages are percent of sludge dry weighttairanchemical.com. Also, mixing requirements differ. Flocculation tanks typically allow minutes for polymer-particle interaction, but sludge dewatering tanks have only seconds of “contact” before press or centrifuge. As Tairan notes, “when using flocculants… mixing takes tens of seconds to minutes, and reaction 15–30 min. In sludge dewatering often has only a few seconds… [so] the conditioning effect decreases as the residence time increases”tairanchemical.com. In practice, this means sludge conditioners must act very rapidly under mechanical shear.

Summary: Flocculants (like polyacrylamide and inorganic flocculants) and coagulants (alum, iron salts, PAC) are used in concert to clarify water by forming settleable flocs. Coagulant aids (often polymeric) boost these processes. After solids are produced, sludge conditioners – including the same polymers or metal salts – are added to improve dewatering. Understanding their definitions and interactions helps engineers and procurement specialists choose the right treatment chemicals. For example, pairing an alum coagulant with a polymer flocculant can improve turbidity removal, while adding a polymer conditioner before a filter press will reduce sludge moisture. Industry sources note that polymers used as flocculants also serve as effective sludge conditionerswww3.epa.govtairanchemical.com, making chemicals like polyacrylamide highly versatile in both municipal water treatment and industrial sludge dewatering applications.

Sources: Authoritative industry and academic sources were consulted, including EPA water treatment manuals and peer-reviewed reviewswww3.epa.govpubmed.ncbi.nlm.nih.gov, as well as Tairan Chemical technical pages on water treatment chemicalstairanchemical.comtairanchemical.comtairanchemical.com. These sources confirm the roles and uses of flocculants, coagulant aids, and conditioners in real-world treatment processes.